|

|

|

|

|

|

|

|

|

|

Pipe Network Fluid Flow

Analysis Systems |

|

|

|

|

PipeNet Standard

| is

a powerful tool in the design of single phase steady flow of fluids in pipes. It provides

a quick and cost-effective means of designing real life problems. |

|

|

|

PipeNet Transient

| provides

a speedy and cost-effective means of in-house rigorous transient analysis. The Transient

Module can be used for predicting pressure surges, calculating hydraulic transient forces

or even modelling control systems in flow networks |

|

|

|

PipeNet

Spray/Sprinkler

| is

a powerful tool in the design of fixed fire-protection systems complying with NFPA and FOC

rules. It can be used to design deluge, ringmain, sprinkler and foam solution systems for

offshore platforms, refineries, petrochemical and chemical plants |

|

|

|

|

|

|

|

PipeNet Standard |

|

| Networks |

| Networks can be defined from a wide choice of elements-pipes,

ducts, nozzles, pumps/fans, filters, non-return valves, control valves, leaks, fixed

pressure drops, orifice plates, properties and specifications. |

| PIPENET has built-in data of fittings (Crane), gases, steam (IFC67

standard) and pipe schedules (ANSI, JIN and DIN). Users can also create their own pump,

pipe schedule, control valve, fittings and fluids data libraries that can be used in any

network. |

| PIPENET allows the properties of the fluid to be constant or to

vary in the network system. |

|

|

| Fittings |

| Multiple fittings can be inserted on a pipe and it is not necessary

to treat them as separate entities. They are simply defined as attributes of a pipe. This

is a powerful feature of PIPENET. |

|

|

| Schematic

Capabilities and On-line Help |

| A network can be defined using schematic or text input. However, a

text input network can also be displayed using the schematic. Results can also be

displayed on the schematic. Online help is also available for more information on the

features of PIPENET. |

|

|

| Pipe

Sizing and Blocked and Broken Pipes |

| PIPENET has very powerful pipe sizing capabilities. It Can select

standard nominal bores from user-defined or built-in pipe schedule data. A blocked or

broken pipe can also be modelled in network. |

|

|

| Cavitation |

| The

program will detect and report the likely occurrence of both deaeration and vaporisation

cavitation. |

| Orifice

Plates |

| Restriction

Orifice plates can be modelled in compliance with Crane, Heriot-watt and

BS 1042, taking

into account downstream pressure recovery. Given the pressure drop the orifice diameter is

determined, and vice-versa. |

| Modelling

of Gases and Low-Pressure Gases |

| These

can be modelled using standard pressure loss correlations and correction factors,

making the module suitable for the design of gas distribution systems. |

| Filters |

| A

filter is available for use where accurate modelling is required. On the other hand,

filters can simply be modelled as fittings |

| Leaks |

| This

is a powerful feature of the program and is particularly useful for flow analysis of

ventilation systems where the handing of leaks is very important. Leaks are modelled in

accordance with the requirements of BS5588. Leaks may be defined as between two nodes of a

network (for instance to represent a leak around a door between rooms) or to the

atmosphere. |

| Control

Valves |

| This

regulates flow or pressure in a network. The valve setting can be specified by the user or

based on a sensor - pressure at a node, flow in a pipe or pressure difference between two

nodes. |

|

Hydraulic Gradient Capability |

| Hydraulic gradient capability calculations can be

performed for incompressible fluids. |

| Nozzles

can be Modelled using Fundamental Equations of Flow |

| Ambient

Pressure Correction |

| Particularly used in ventilation system calculations involving tall

chimney stacks, automatic correction for the variation in ambient pressure with height is

available. |

| Output |

| Output

reports can be created using Word, Write or PIPENET Output Browser. |

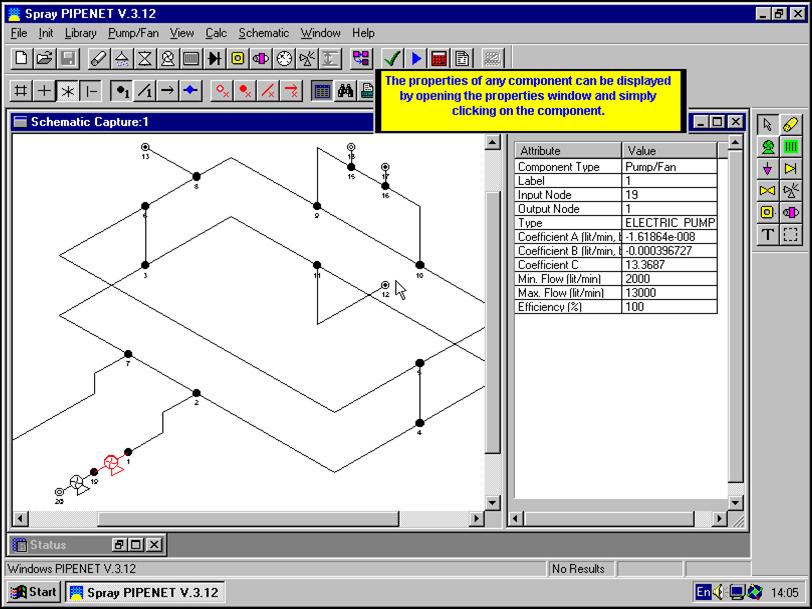

| Pump/Fan |

| A

standard PIPENET pre-processor is provided for the creation of libraries of performance

characteristics. These can be readily accessed to include pumps/fans in networks. A given

pump type need therefore be input to the module only once for it to be available for

repeated use in different network designs. Pumps, including booster pumps, can be

connected in series or parallel at any point in the network. |

|

|

|

|

[Top to this page] |

|

|

|

PipeNet

Transient |

|

| Built-in

Element Models |

| The

following range of element models is available at present |

|

í |

Pipes |

|

í |

Pumps:Simple

pump, Turbo pump |

|

í |

| Valves: |

Operating valve, non-return valve, check valve, fluid damped check valve,

liquid surge relief valve, regulator valve, inertial check valve. |

|

|

í |

Tanks:Accumulator

tank, simple tank, surge tank |

|

í |

Vacuum

breaker / Air release valve |

|

í |

Caissons |

|

í |

Control

Systems: Pressure of Flow sensor, PID controller, Transfer function |

|

| New

models can be developed if required. |

| Fittings |

| Multiple

fittings can be inserted on a pipe and it is not necessary to treat them as separate

entities. They are simply defined as attributes of a pipe. This is a powerful feature of

PIPENET. |

| Time

Operation of Valves |

| The

operating valve model can be used to represent a manual valve or a control valve. In the

case of a manual valve, its operation would be directly specified by a user-defined

boundary condition. In the case of a control valve, the operation would be defined by a

signal from the control loop. |

| Operation

of Pumps (Simple or Turbo) |

| The

pressure increase provided by a simple pump depends on its speed and performance curve.

The performance curve can be entered and saved as library. The pump speed is specified

directly or by a signal from the control loop. The turbo pump can additionally handle the

'spin down' due to pump failure. |

| Control

Systems |

| Control

systems allow components such as pumps or valves to react to changes in pressure or

flowrate in some part of the network. |

| A

sensor measures an instantaneous reading for pressure or flowrate, which is converted to a

signal for the controlled device by means of a PID controller. Transfer functions can also

be included in the control loop to model the dynamics of the sensor and the controlled

device. |

| Hydraulic

Transient Forces |

| Pipework

can experience significant stresses and movements, or even sustain damage, due to fluid

transient phenomena such as water hammer. PIPENET can calculate hydraulic transient forces

and these can be read by pipe stress or structural analysis programs for further

processing. |

| Initial

Conditions |

| PIPENET

can automatically generate the initial steady state solution. For cases where the starting

point is not steady state, the user can supply own starting condition. |

| Stationary

Initial Condition |

| Often a pipe network system would start from a stationary condition where the

flow is zero throughout the system. It is possible to do this automatically. |

| Vapour

Cavitation Modelling |

| Under transient flow conditions pipework can locally experience very low

pressures. Generally these would be cyclic in nature. Constant formation and collapse of

vapour cavities would accompany this phenomenon in cycles. PIPENET can model this. |

| Automatic

Calculation of Wave Speed and Time Step |

| Under transient flow conditions, the effect of a disturbance makes itself felt

throughout the system in the form of waves. The wave speed depends on parameters such as

the modulus of elasticity of the pipe material, diameter, wall thickness, the Poisson's

ratio and the compressibility of the fluid. The wave speed is of fundamental importance,

and PIPENET can calculate it automatically. The program can also determine the time step

for calculation automatically. The user can optionally specify both the wave speed and the

time step. |

| Tabular

Output |

| Typically, a large amount of calculated results would be produced by transient

analysis. For this reason, the Transient module allows the user to define which variables

are to be output and in what format. |

| Graphical

Output |

| While tabular output is useful for a thorough analysis, graphical output can be

used to get a quick overview. The Transient module allows the user to output selected

variables graphically. The graphs can also be viewed as movies in real time. |

| Forces

Output |

| The

force-time history can be output in the form of a forces file. This file is specifically

intended for further processing by pipe stress or structural analysis program. |

| Functions

available for Boundary Conditions |

| The

following functions may be used for specifying the boundary conditions. (These are time

dependent.) |

|

í |

Constant |

í |

Power Ramp |

|

í |

Sine Wave |

í |

Exponential |

|

í |

Damped Sine Wave |

í |

Asymmetric Pulse |

|

í |

Profile -

linear, step or cubic |

|

|

|

|

|

|

|

[Top to this page] |

|

|

|

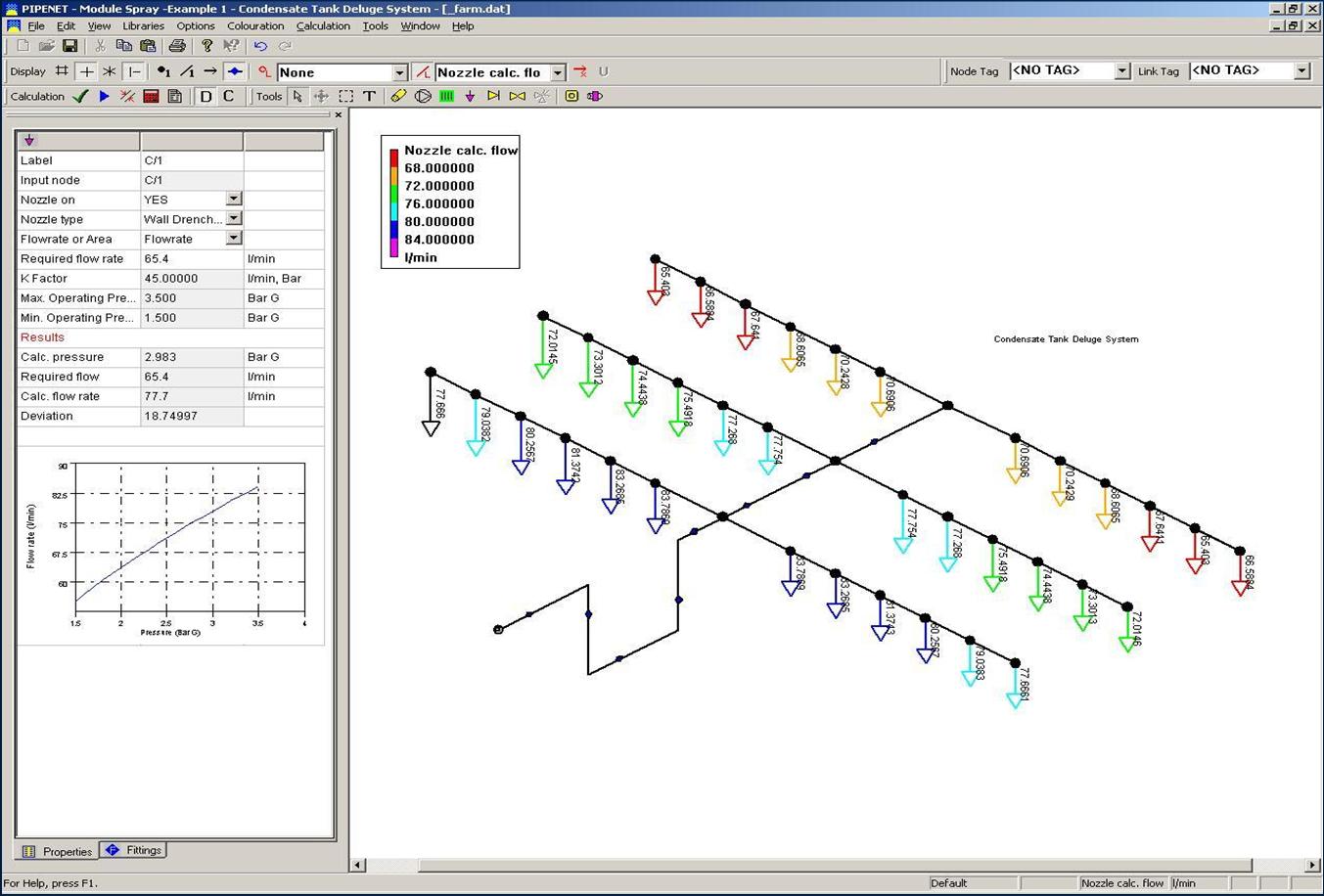

PipeNet Spray/Sprinkler |

|

| Network |

| Networks

can be defined from a wide choice of elements - pipes and fittings, nozzles, deluge

valves, pumps/fans, filters, non-return valves, orifice plates, special equipment items,

specifications and overboard dump valves. |

| PipeNet has built-in data of fittings, pipe

linings and pipe schedules. Users can also create their own pump, pipe schedule, pipe

lining, nozzle and deluge valve data libraries that can be used in any network. |

| Fittings |

| Multiple

fittings can be inserted on a pipe and it is not necessary to treat them as separate

entities. They are simply defined as attributes of a pipe. This is a powerful feature of

PipeNet. |

| Schematic

Capabilities and On-line Help |

| A

network can be defined using schematic or text input. However, a text input network can

also be displayed using the schematic. Results can also be displayed on the schematic.

On-line help is also available for more information on the features of PipeNet. |

| Ringmain

Capabilities |

| Fire

pumps (including booster pumps) may be connected in series or in parallel anywhere in the

network. One or more of them may be operating in given scenario, and it is easy to switch

pumps on and off. For ringmain systems, the program handles the following tasks: |

|

í |

pump selection

calculations using manufacturer's pump data |

|

í |

connecting pumps

or booster pumps in series or in parallel at any point in the network |

|

í |

modelling of

conventional deluge valves in addition to constant flow deluge valves |

|

í |

attachment of

monitors and hydrants |

|

í |

performing case

studies with different fire scenarios |

|

í |

use of lined and

unlined pipes in the same system |

|

í |

modelling

operation of isolation valves |

|

í |

connecting

loops, grids and trees in any combination |

|

í |

modelling of

breaks and blocks in pipework |

|

| Deluge

Valves |

Deluge valves may be of conventional "clack" shut type or

"constant flow" type.

Monitors and hydrants may be attached anywhere in the network. Loops, grids and trees may

be incorporated in any combination. Lined and unlined pipes can be used in the same

system. Pump selection calculations can be performed or manufacturer's data can be used to

model the exact behaviour of the system once a pump has been selected. The module makes it

possible to perform cases studies with different fire scenarios. Breaks and blocks in the

pipework may be modelled with ease. |

| Deluge

System Capabilities |

| A

powerful range of alternative calculation types is available. The Program can

automatically identify the most remote nozzle and set its flow rate or the average density

option may be chosen. The user may even specify the flow rate or flow density at a

selected nozzle, or the available inlet pressure or flow rate. Orifice plates may be sized

to balance the pressure required by the deluge system and the pressure available in the

ringmain. For deluge systems the program can handle. |

|

í |

automatic

identification of the most remote nozzle and setting its flow rate |

|

í |

sizing orifice

plates to match the pressure required by the deluge system |

|

í |

specifying the

flow rate or the flow density at a specific nozzle |

|

í |

specifying the

available inlet pressure |

|

í |

selecting the

average density option |

|

| Pipe

Schedule |

| Pipes

may be lined or unlined, selected from eight built-in pipe schedules and three pipe

linings. Alternatively, users can set up their own pipe schedule and lining data. Pipe

sizes can be referred to by nominal or external diameters. A network can include several

different lined and unlined pipe types. |

| Pipe

Sizing |

| The

user may leave some or all pipe sizes unspecified. PIPENET will automatically suggest

appropriate pipe sizes based on the user selected pipe schedule |

| Orifice

Plates |

| Restriction

Orifice plates can be modelled in compliance with Crane, Heriot-watt and BS1042, taking

into account downstream pressure recovery. Given the pressure drop the orifice diameter is

determined, and vice-versa. |

| Remote

Nozzle Calculation |

| Calculations

can match the minimum flow rate required at the nozzle that is hydraulically most remote.

Nozzles may also be switched on or off individually or in banks. |

| Materials

Take-Off |

| Materials

take-off tables can also be produced for weight and cost estimation purposes. |

| Output |

| Output

reports can be created using Word, Write or PIPENET Output Browser. |

| Pump/Fan |

| A

standard PIPENET pre-processor is provided for the creation of libraries of performance

characteristics. These can be readily accessed to include pumps, fans etc. in networks. A

given pump type need therefore be input to the module only once for it to be available for

repeated use in different network designs. |

|

|

|

|

|

|

|

|

|

[Top to this page] |

|

|